As robots become increasingly integrated into various industries, including manufacturing, healthcare, and transportation, the need for rigorous durability testing has never been more critical. Robot durability testing is a comprehensive process designed to evaluate the reliability, performance, and lifespan of robots under various environmental and operational conditions. In this article, we will delve into the world of robot durability testing, exploring its significance, methodologies, and benefits.

Why is Robot Durability Testing Crucial?

Robots are complex systems consisting of multiple components, including mechanical, electrical, and software elements. These components are susceptible to wear and tear, damage, and failure, which can lead to costly repairs, downtime, and compromised performance. Robot durability testing helps identify potential weaknesses and vulnerabilities, allowing manufacturers to address these issues before the robots are deployed in real-world applications.

Durability testing also plays a vital role in ensuring the safety of humans and the environment. Robots that are not designed or tested to withstand various environmental conditions, such as extreme temperatures, humidity, or vibrations, can malfunction or fail, causing accidents or injuries. By subjecting robots to rigorous durability testing, manufacturers can guarantee that their products meet the required safety standards and regulations.

Methodologies and Types of Robot Durability Testing

Robot durability testing involves a range of methodologies and techniques, including:

- Environmental Testing: This type of testing exposes robots to various environmental conditions, such as temperature, humidity, vibration, and radiation, to evaluate their performance and reliability.

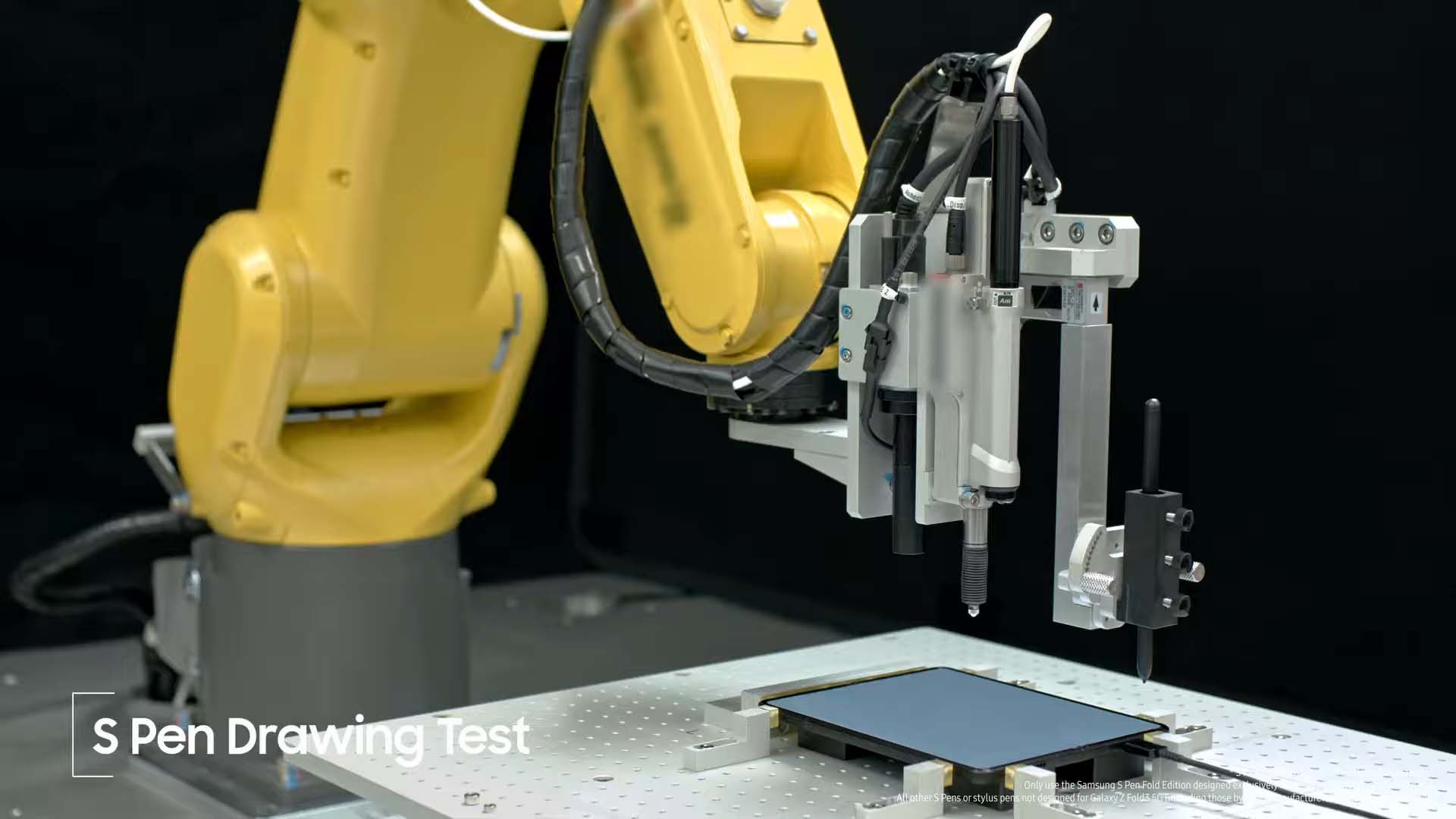

- Mechanical Testing: Mechanical testing involves subjecting robots to mechanical stresses, such as shocks, drops, and vibrations, to assess their structural integrity and durability.

- Electrical Testing: Electrical testing evaluates the performance and reliability of robots’ electrical systems, including power supplies, motors, and control systems.

- Software Testing: Software testing involves evaluating the performance, reliability, and security of robots’ software systems, including operating systems, applications, and algorithms.

- Reliability Testing: Reliability testing involves subjecting robots to continuous operation over an extended period to evaluate their reliability and performance.

Benefits of Robot Durability Testing

The benefits of robot durability testing are numerous and significant. Some of the most notable advantages include:

- Improved Reliability: Durability testing helps identify and address potential weaknesses, resulting in more reliable and robust robots.

- Enhanced Performance: By evaluating robots’ performance under various conditions, manufacturers can optimize their design and functionality.

- Increased Safety: Durability testing ensures that robots meet required safety standards and regulations, reducing the risk of accidents and injuries.

- Reduced Maintenance Costs: By identifying and addressing potential issues, manufacturers can reduce maintenance costs and minimize downtime.

- Competitive Advantage: Companies that invest in rigorous durability testing can differentiate themselves from competitors and establish a reputation for producing high-quality, reliable robots.

Real-World Examples of Robot Durability Testing

Several companies have successfully implemented robot durability testing programs, resulting in significant improvements in reliability, performance, and safety. For example:

- Boston Dynamics: The robotics company, acquired by Hyundai Motor Group, has developed a range of robots, including the Atlas and Spot, which have undergone rigorous durability testing, including environmental and mechanical testing.

- KUKA: The German robotics company has implemented a comprehensive durability testing program for its industrial robots, which involves environmental, mechanical, and electrical testing.

- NASA: The space agency has conducted extensive durability testing on its robots, including the Robonaut, which has undergone environmental and mechanical testing to ensure its reliability and performance in space missions.

FAQ

Q: What is the purpose of robot durability testing?

A: The primary purpose of robot durability testing is to evaluate the reliability, performance, and lifespan of robots under various environmental and operational conditions.

Q: What types of testing are involved in robot durability testing?

A: Robot durability testing involves environmental, mechanical, electrical, software, and reliability testing.

Q: Why is durability testing important for robot safety?

A: Durability testing ensures that robots meet required safety standards and regulations, reducing the risk of accidents and injuries.

Q: Can robot durability testing reduce maintenance costs?

A: Yes, by identifying and addressing potential issues, manufacturers can reduce maintenance costs and minimize downtime.

Q: How can companies benefit from robot durability testing?

A: Companies can benefit from durability testing by improving reliability, enhancing performance, increasing safety, reducing maintenance costs, and establishing a competitive advantage.

Conclusion

Robot durability testing is a critical process that ensures the reliability, performance, and safety of robots in various industries. By subjecting robots to rigorous testing, manufacturers can identify potential weaknesses, optimize design and functionality, and guarantee compliance with safety standards and regulations. As the demand for robots continues to grow, the importance of durability testing will only increase, driving innovation and improvement in the field of robotics. By investing in comprehensive durability testing programs, companies can establish a reputation for producing high-quality, reliable robots, ultimately contributing to the advancement of the robotics industry as a whole.

Closure

Thus, we hope this article has provided valuable insights into The Importance of Robot Durability Testing: Ensuring Reliability and Performance. We thank you for taking the time to read this article. See you in our next article!